Description

ABSTRACT:

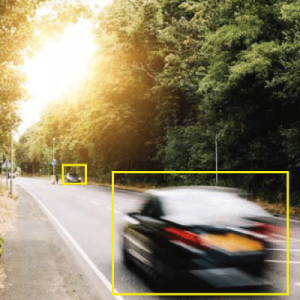

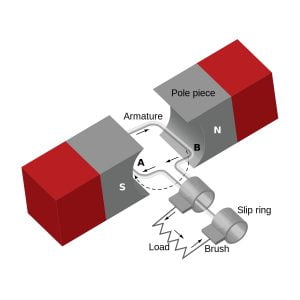

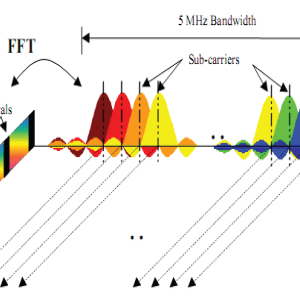

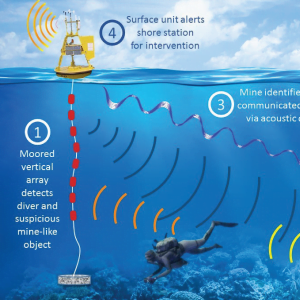

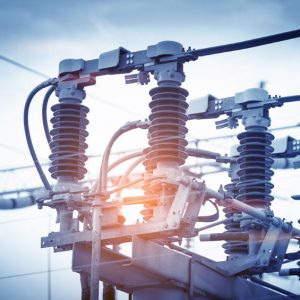

Wireless Power Transmission With Single Phase Inverter using magnetic resonance is the technology that could set humans free from annoying wires. In fact, the WPT adopts the same basic theory which has already been developed for at least 30 years with the term inductive power transfer. WPT technology is developed rapidly in recent years. At kilowatts power level, the transfer distance increases from several millimeters to several hundred millimeters with a grid to load efficiency above 90%. The advances make the WPT very attractive to the electric vehicle (EV) charging applications in both stationary and dynamic charging scenarios. This project reviewed the technologies in the WPT area applicable to EV wireless charging. By introducing WPT in EVs, the obstacles of charging time, range, and cost can be easily mitigated. Battery technology is no longer relevant in the mass market penetration of EVs. It is hoped that researchers could be encouraged by the state-of-the-art achievements, and push forward the further development of WPT as well as the expansion of EV.

INTRODUCTION

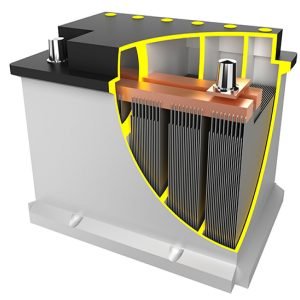

For energy, the environment, and many other reasons, electrification for transportation has been carried out for many years. In railway systems, the electric locomotives have already been well developed for many years. A train runs on a fixed track. It is easy to get electric power from a conductor rail using pantograph sliders. However, for electric vehicles (EVs), the high flexibility makes it not easy to get power in a similar way. Instead, a high-power and large-capacity battery pack is usually equipped as an energy storage unit to make an EV operate for a satisfactory distance. Until now, EVs are not so attractive to consumers even with many government incentive programs. Government subsidies and tax incentives are key to increasing the market share of EVs today. The problem for an electric vehicle is nothing else but the electricity storage technology, which requires a battery which is the bottleneck today due to its unsatisfactory energy density, limited lifetime, and high cost. In an EV, the battery is not so easy to design because of the following requirements: high energy density, high power density, affordable cost, long cycle lifetime, good safety, and reliability, which should be met simultaneously. Lithium-ion batteries are recognized as the most competitive solution to be used in electric vehicles . However, the energy density of the commercialized lithium-ion battery in EVs is only 90?100Wh/kg for a finished pack.1 This number is so poor compared with gasoline, which has an energy density of about 12 000 ?Wh/kg. To challenge the 300-mile range of an internal combustion engine power vehicle, a pure EV needs a large number of batteries which are too heavy and too expensive. The lithium-ion battery cost is about 500$/kWh at the present time. Considering the vehicle’s initial investment, maintenance, and energy cost, the owning of a battery electric vehicle will make the consumer spend an extra 1000$/year on average compared with a gasoline-powered vehicle. Besides the cost issue, the long charging time of EV batteries also makes the EV not acceptable to many drivers. For a single charge, it takes about one half-hour to several hours depending on the power level of the attached charger, which is many times longer than the gasoline refueling process.

EXISTING SYSTEM

In an EV, the battery is not so easy to design because of the following requirements: high energy density, high power density, affordable cost, long cycle lifetime, good safety, and reliability, which should be met simultaneously. Lithium-ion batteries are recognized as the most competitive solution to be used in electric vehicles [1]. However, the energy density of the commercialized lithium-ion battery in EVs is only 90?100Wh/kg for a finished pack [2].1 This number is so poor compared with gasoline, which has an energy density of about 12 000 Wh/kg. To challenge the 300-mile range of an internal combustion engine power vehicle, a pure EV needs a large number of batteries which are too heavy and too expensive.

PROPOSED SYSTEM

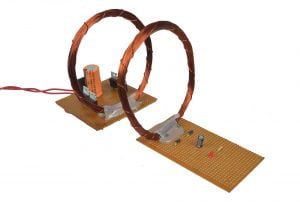

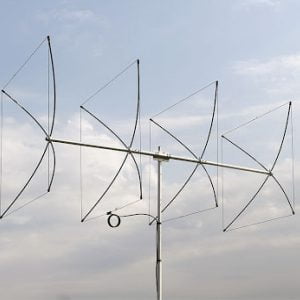

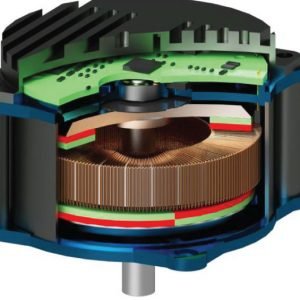

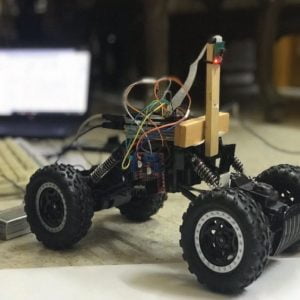

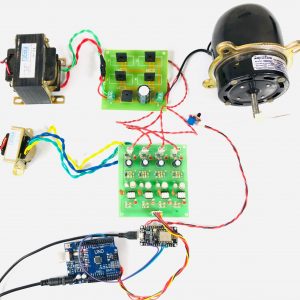

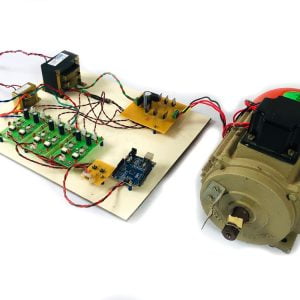

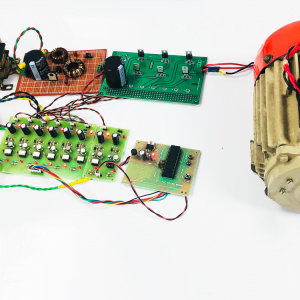

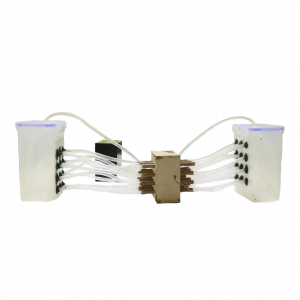

This project starts with the basic WPT theory, and then gives a brief overview of the main parts in a WPT system, including the magnetic coupler, compensation network, power electronics converter, study methodology, and its control, and some other issues like the safety considerations. By introducing the latest achievements in the WPT area, we hope the WPT in EV applications could gain widespread acceptance in both theoretical and practical terms. Also, we hope more researchers could have an interest and make more brilliant contributions in the development of WPT technology.?

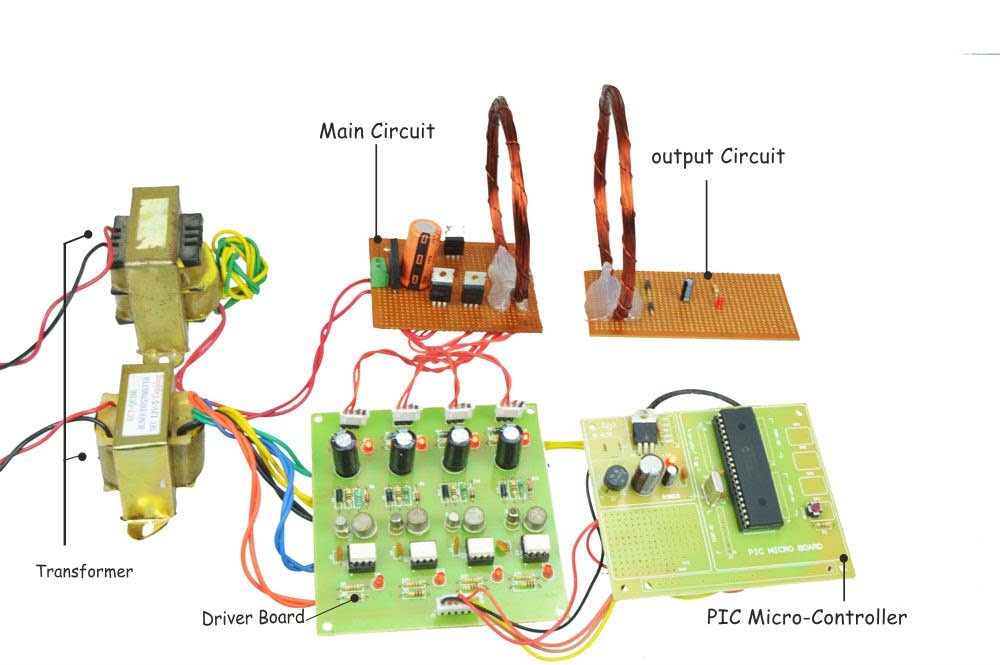

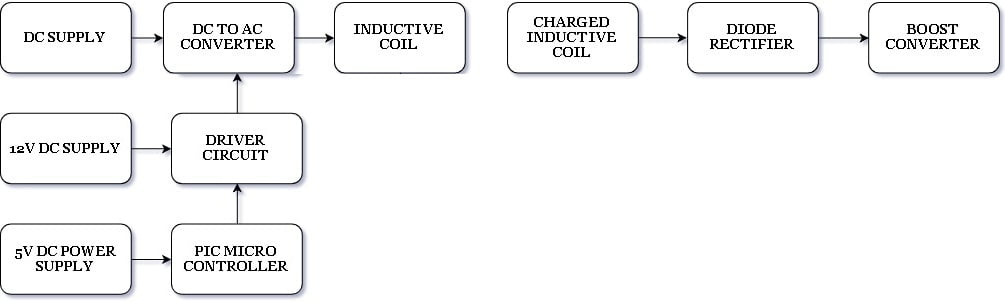

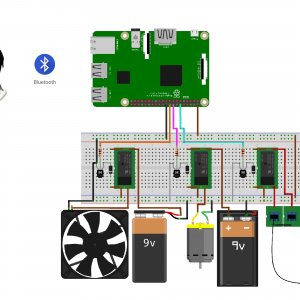

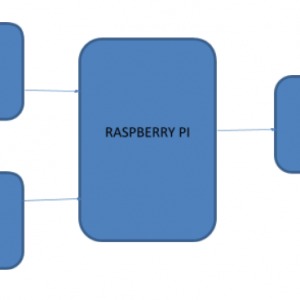

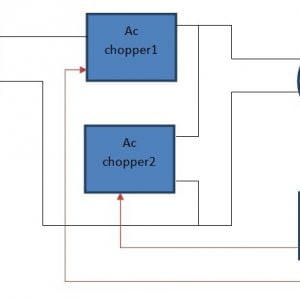

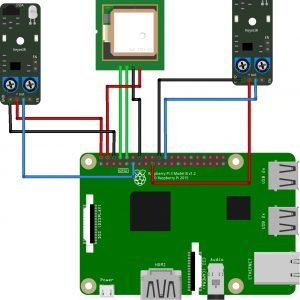

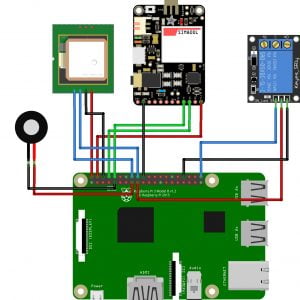

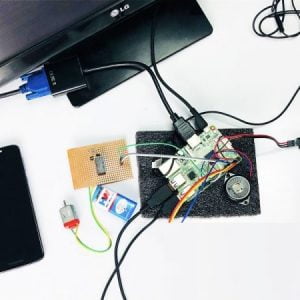

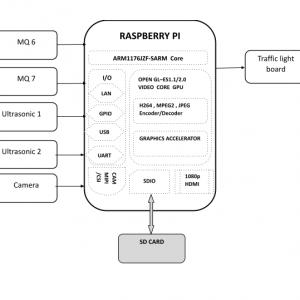

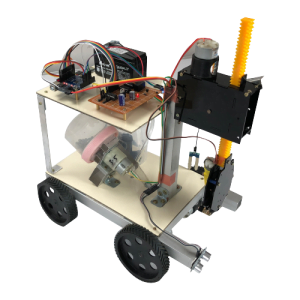

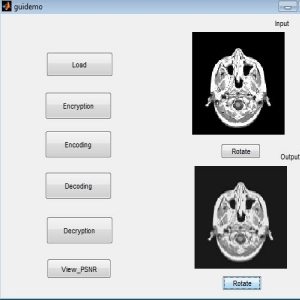

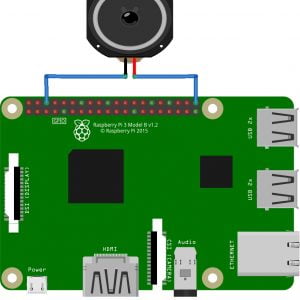

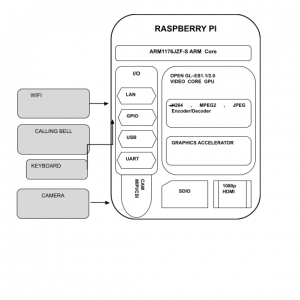

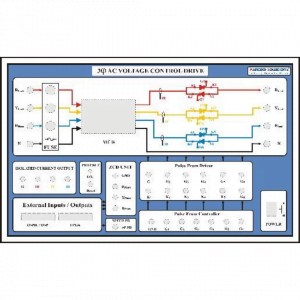

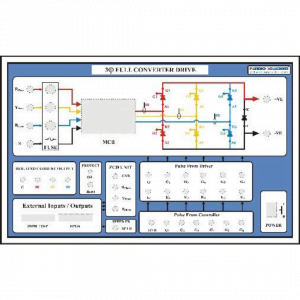

BLOCK DIAGRAM

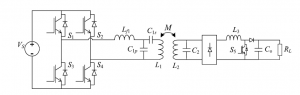

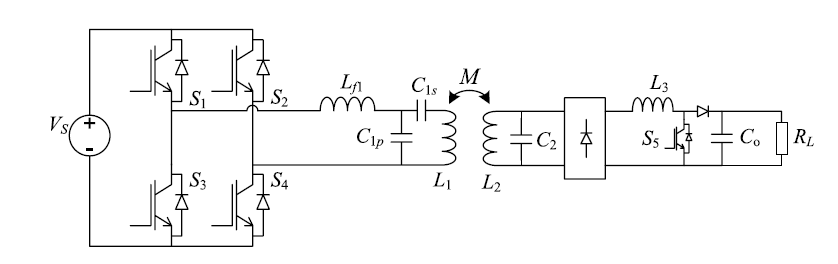

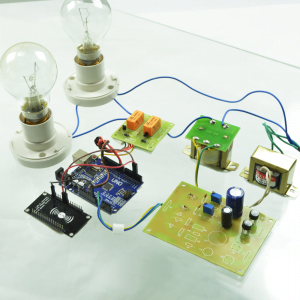

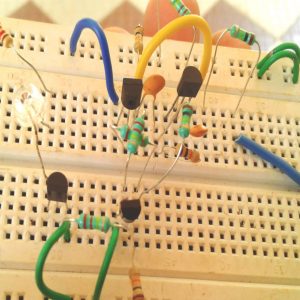

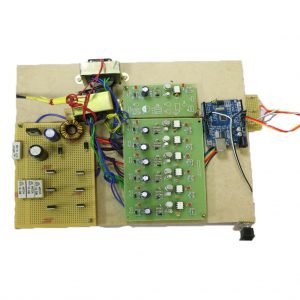

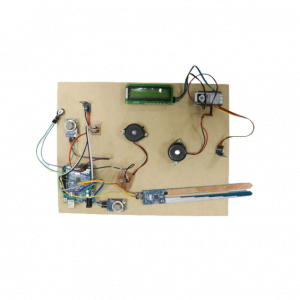

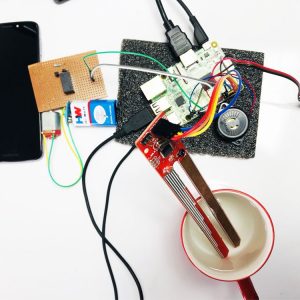

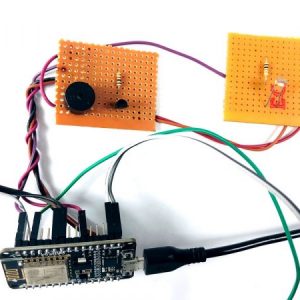

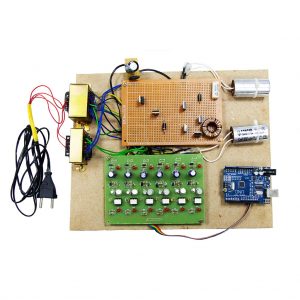

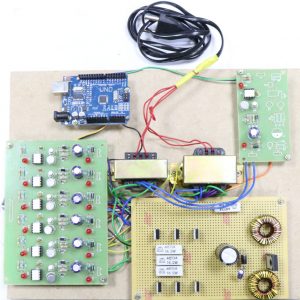

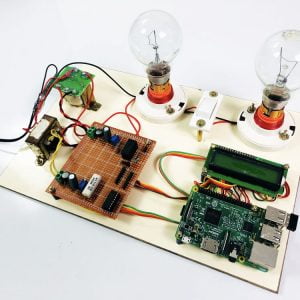

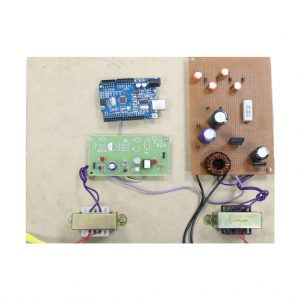

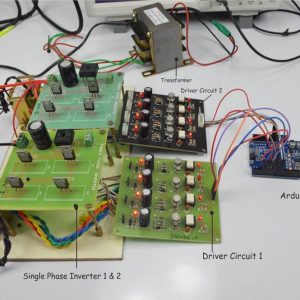

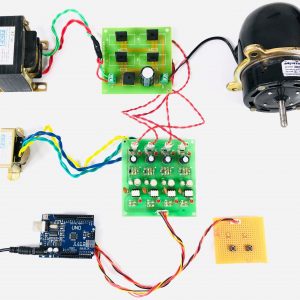

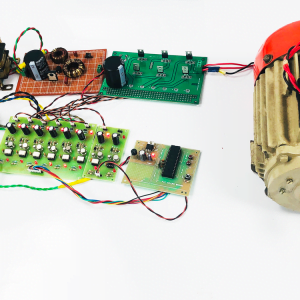

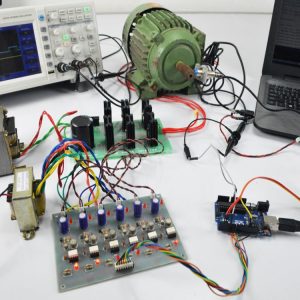

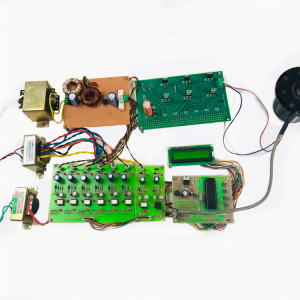

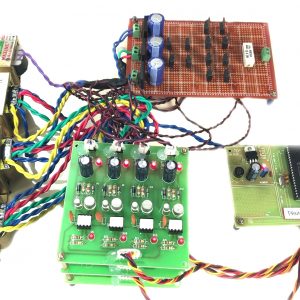

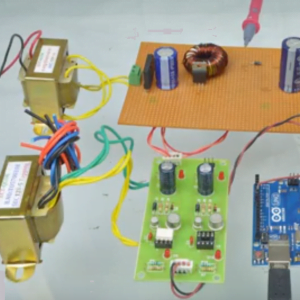

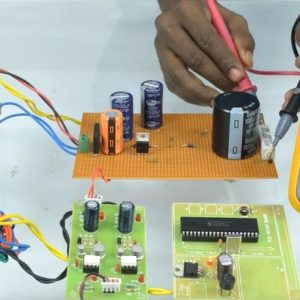

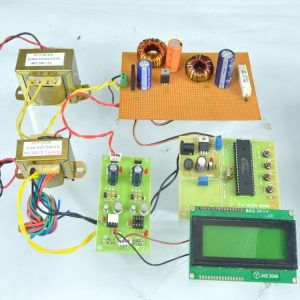

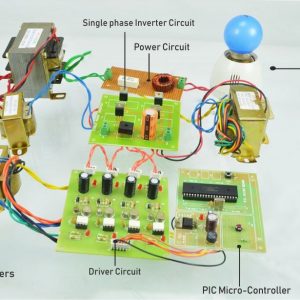

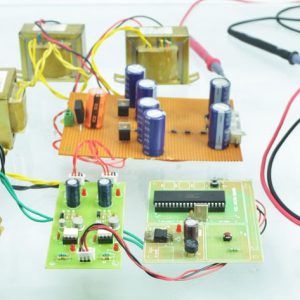

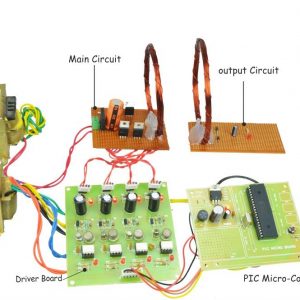

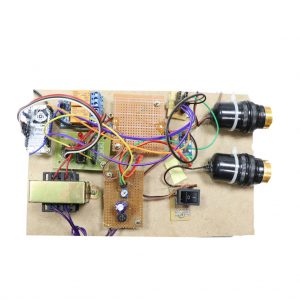

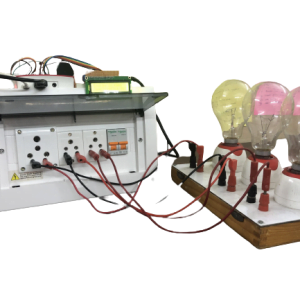

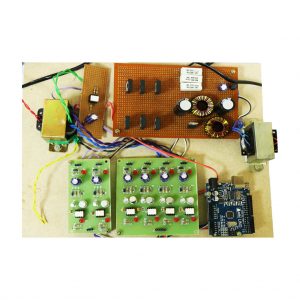

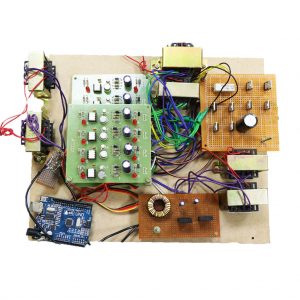

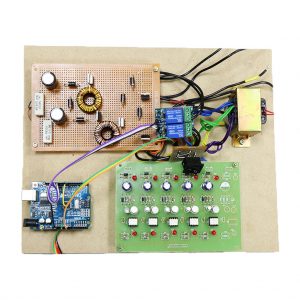

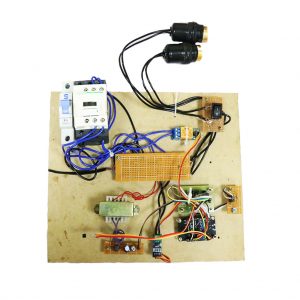

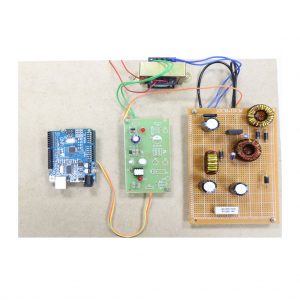

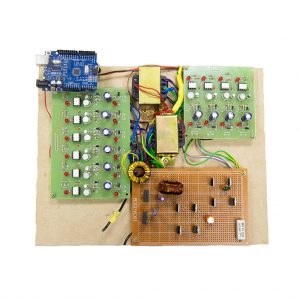

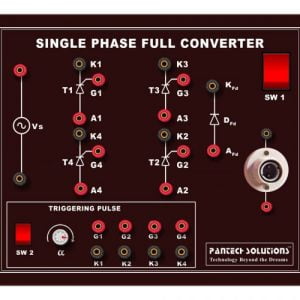

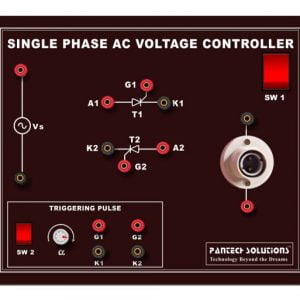

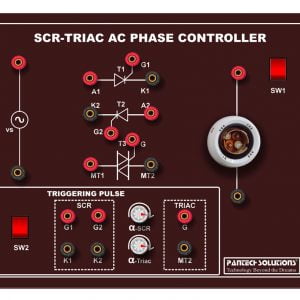

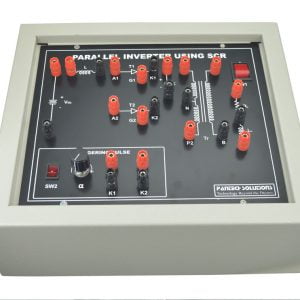

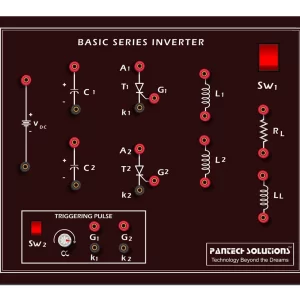

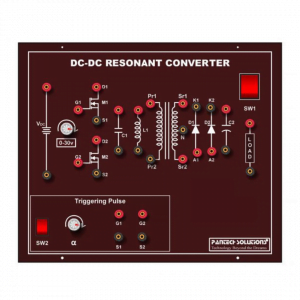

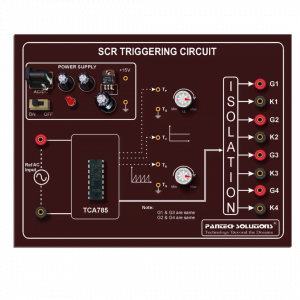

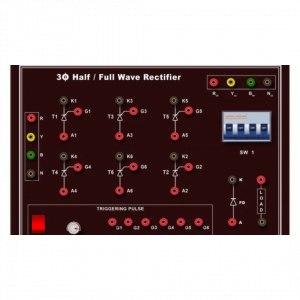

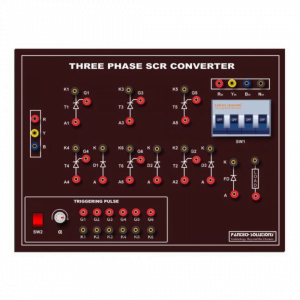

CIRCUIT DIAGRAM

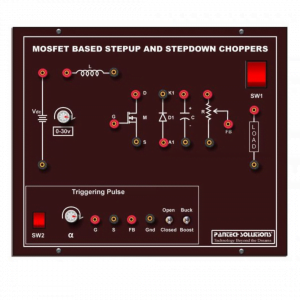

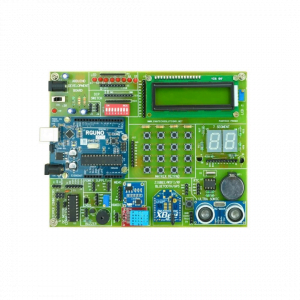

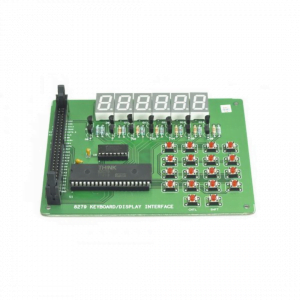

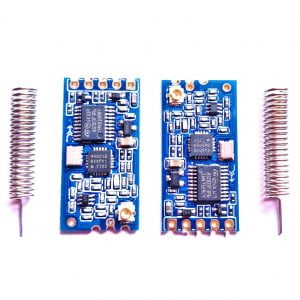

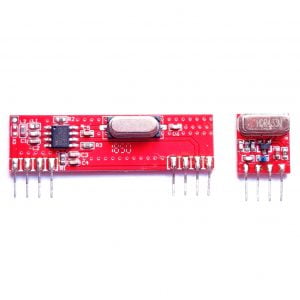

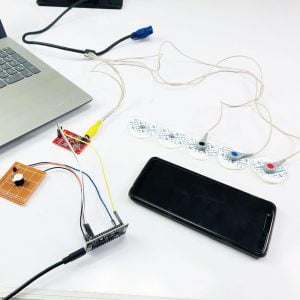

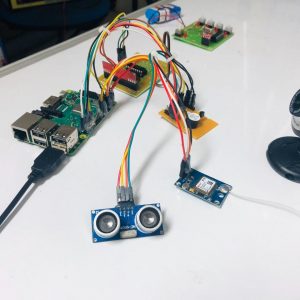

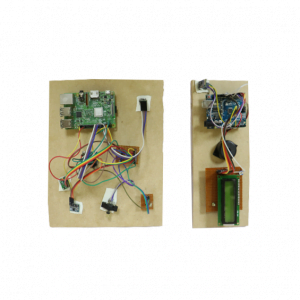

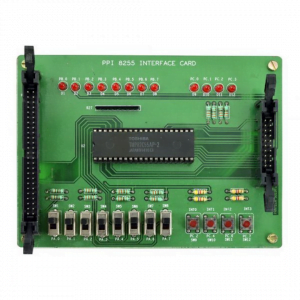

HARDWARE & SOFTWARE REQUIREMENTS

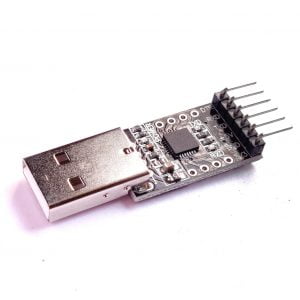

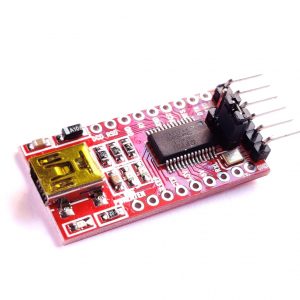

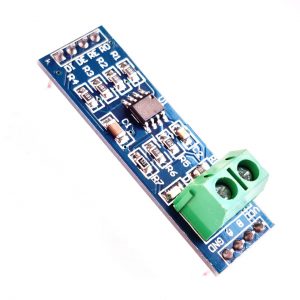

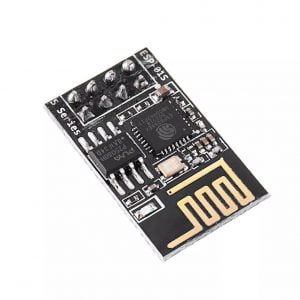

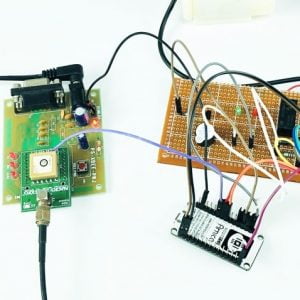

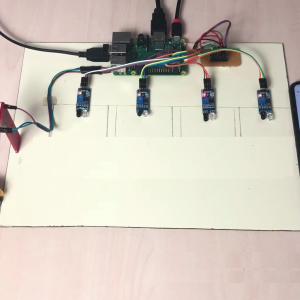

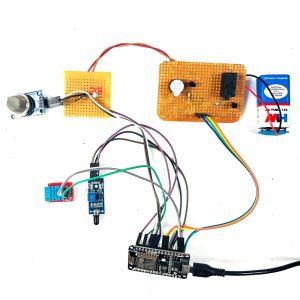

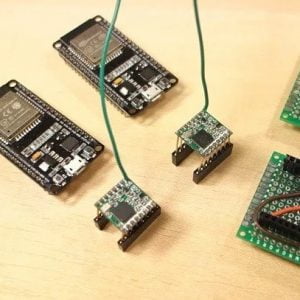

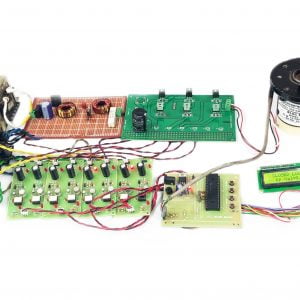

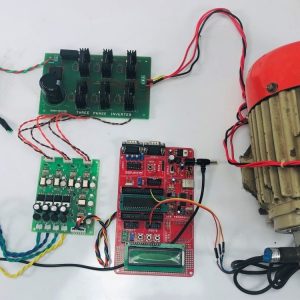

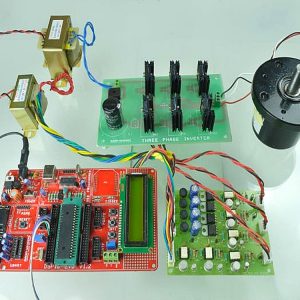

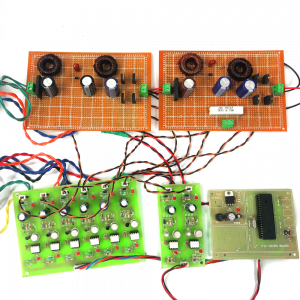

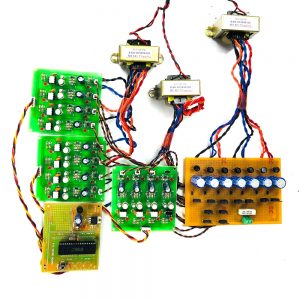

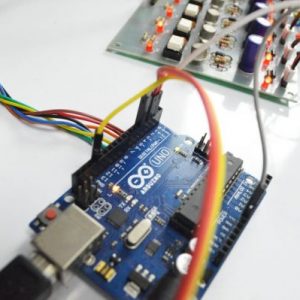

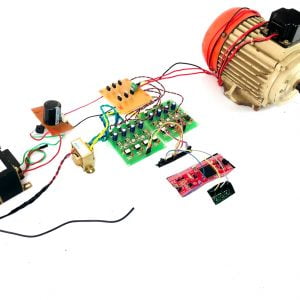

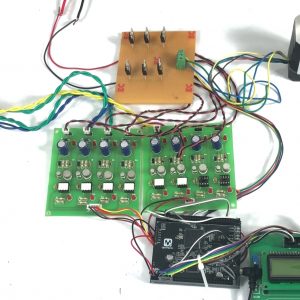

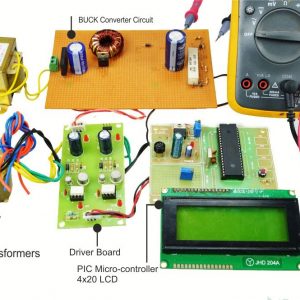

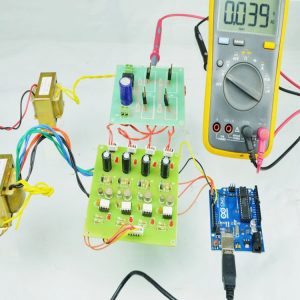

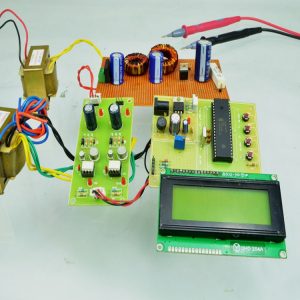

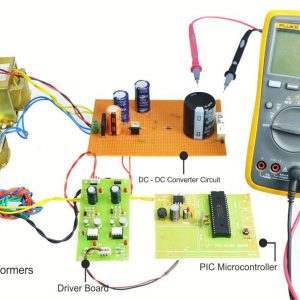

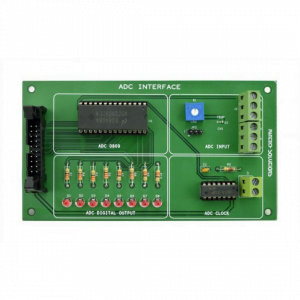

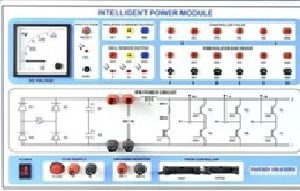

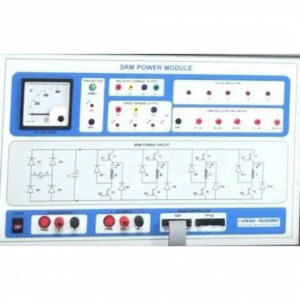

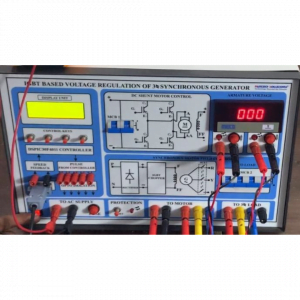

HARDWARE

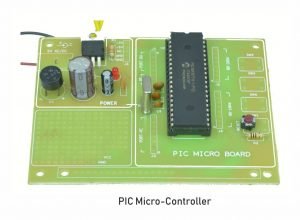

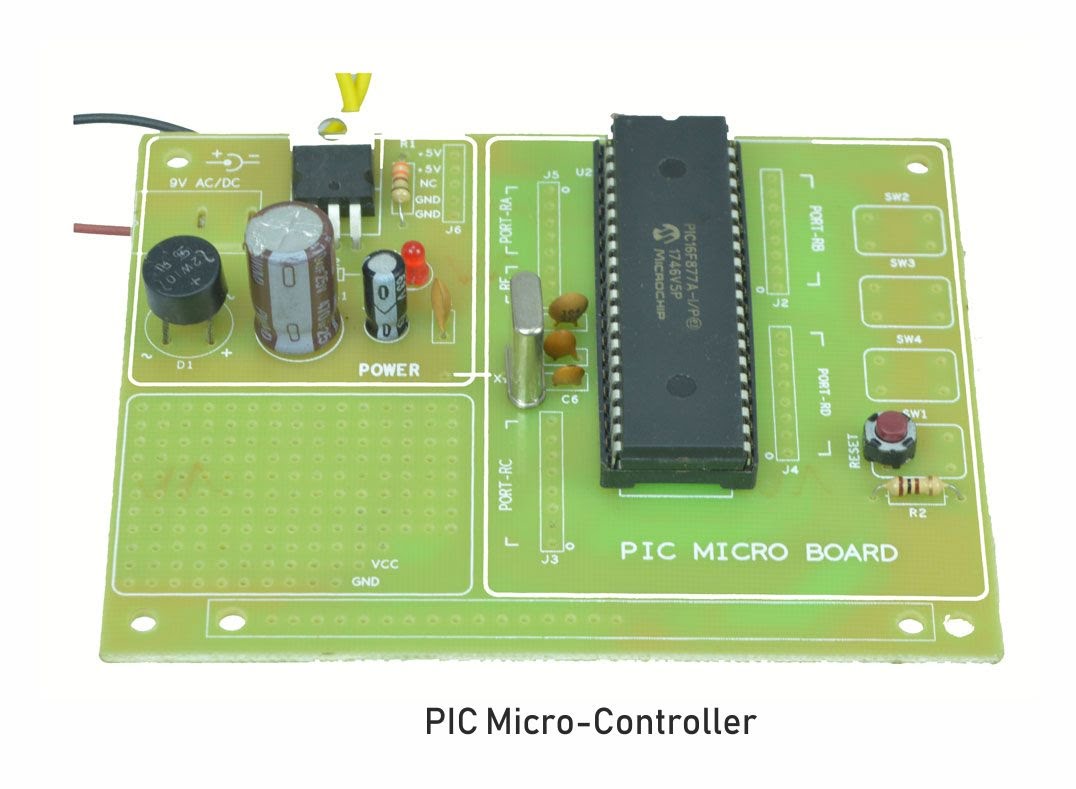

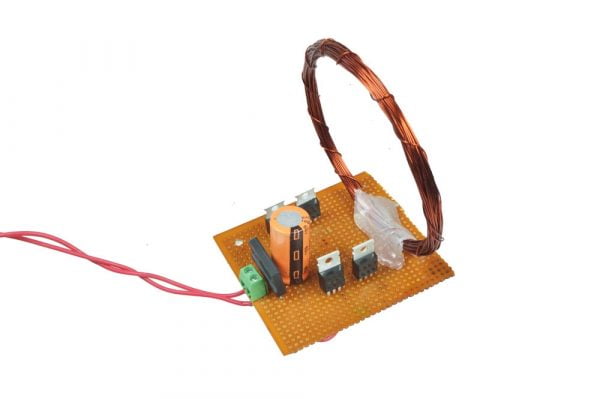

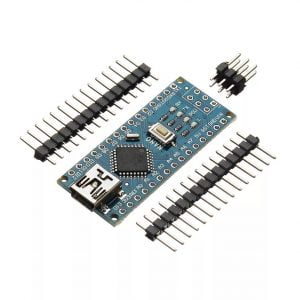

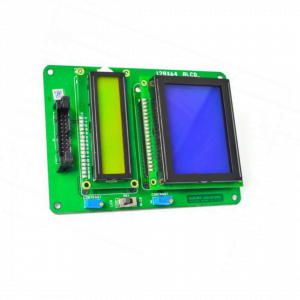

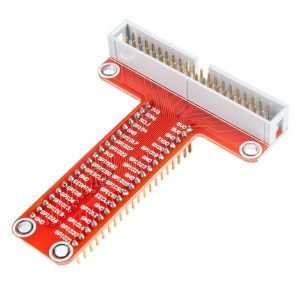

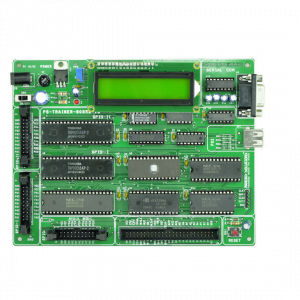

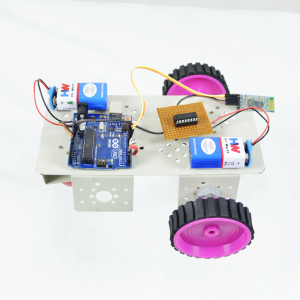

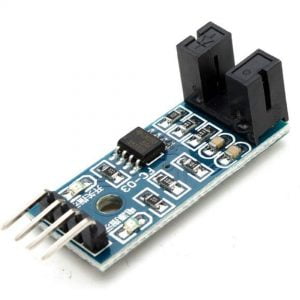

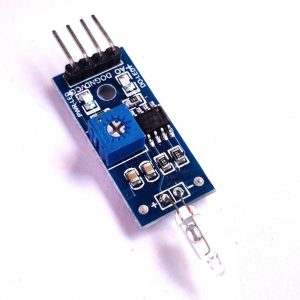

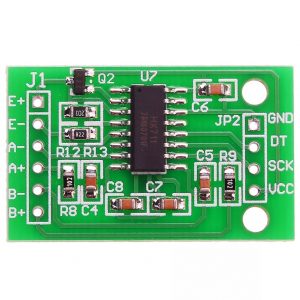

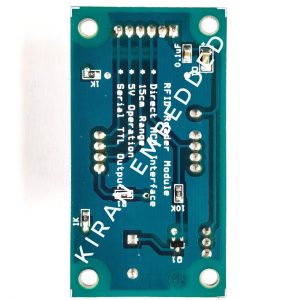

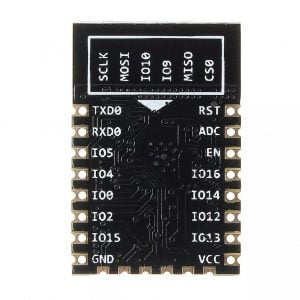

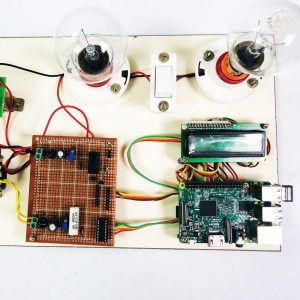

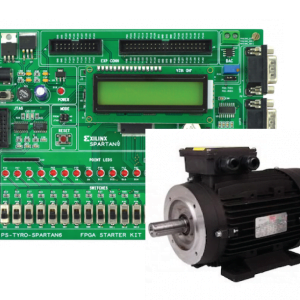

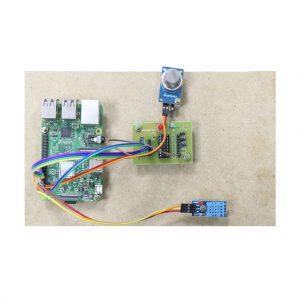

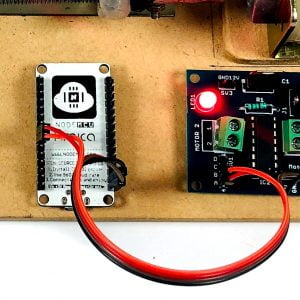

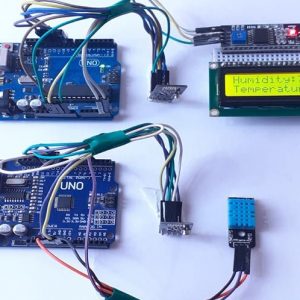

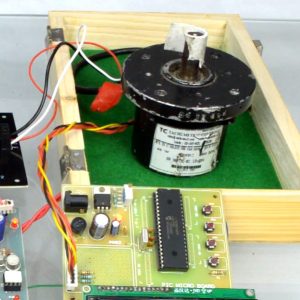

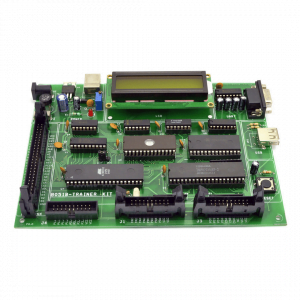

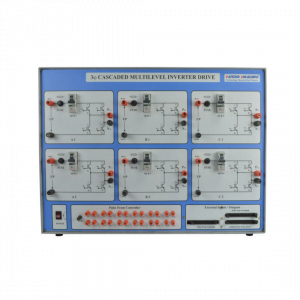

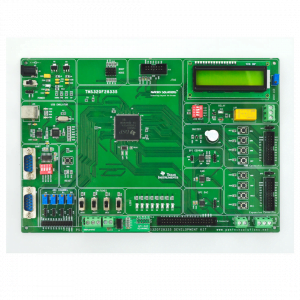

- PIC Controller

Wireless Power Transmission With Single Phase Inverter 7

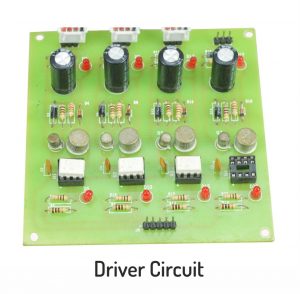

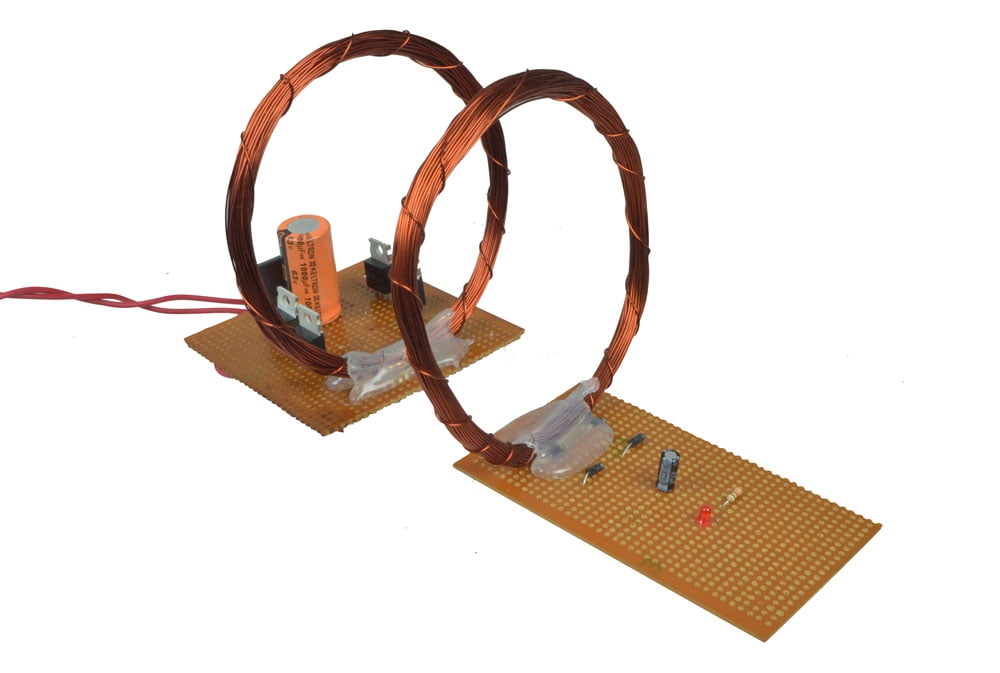

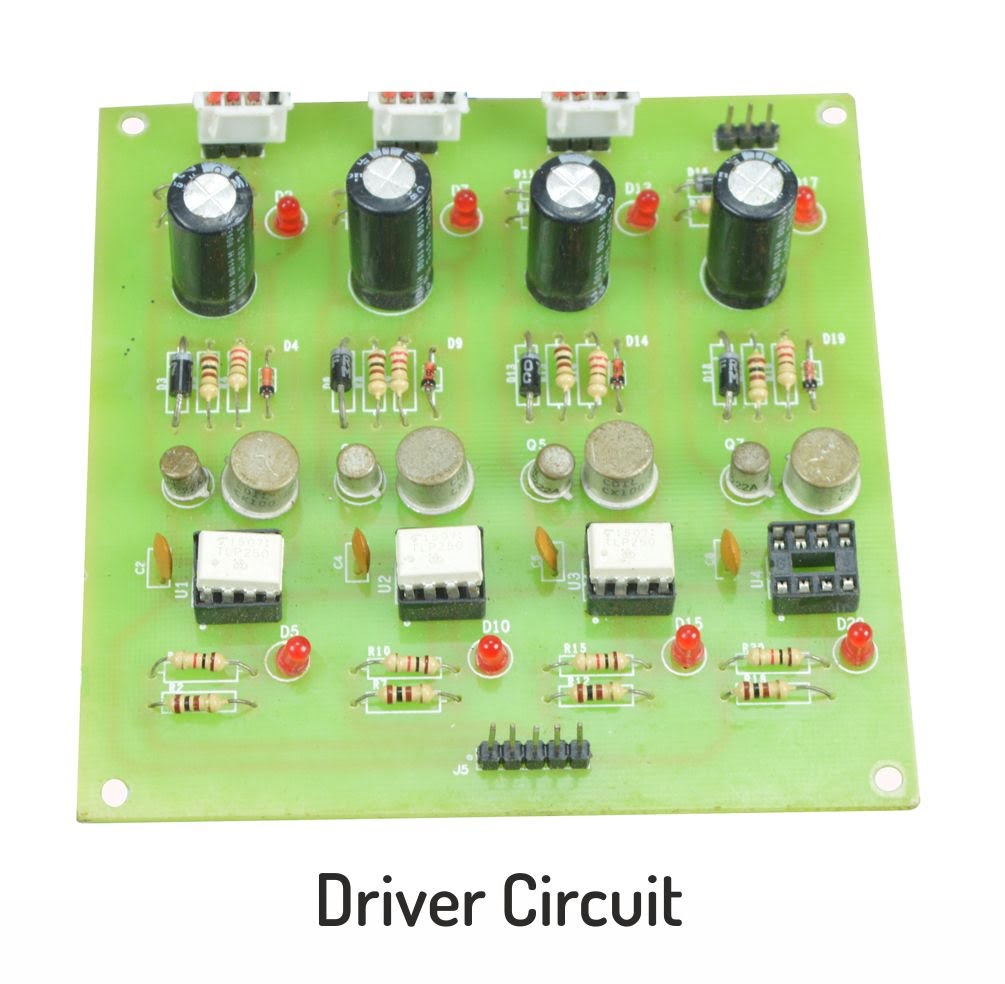

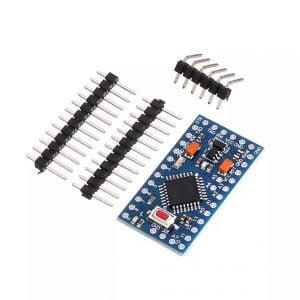

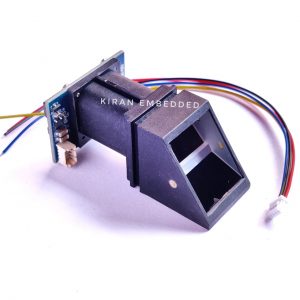

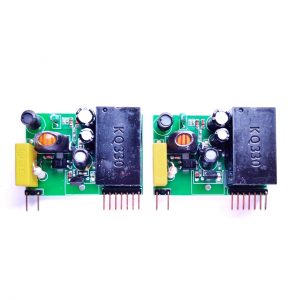

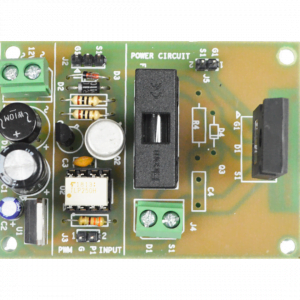

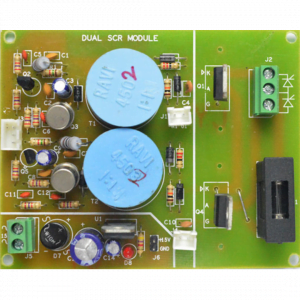

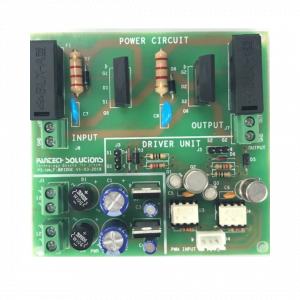

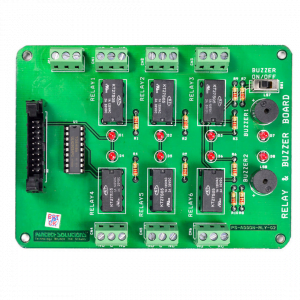

- Driver Board

Wireless Power Transmission With Single Phase Inverter 5

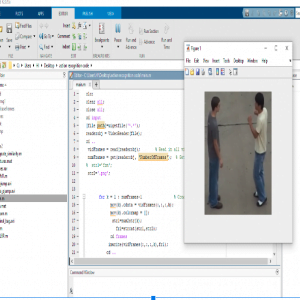

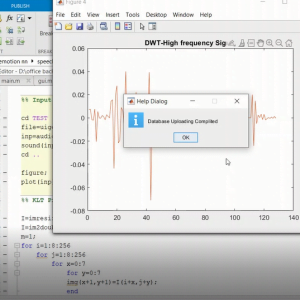

SOFTWARE

- MATLAB ? SIMULINK

ADVANTAGES

- Reasonable Cost.

- Easy way of POWER Transfer.

- Wirelessly transferring energy charging becomes the easiest task.

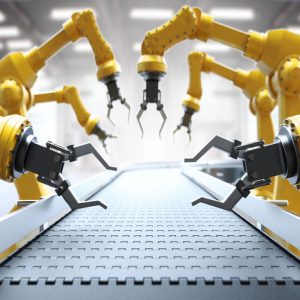

APPLICATIONS

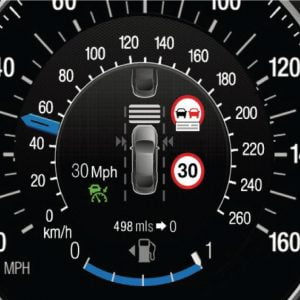

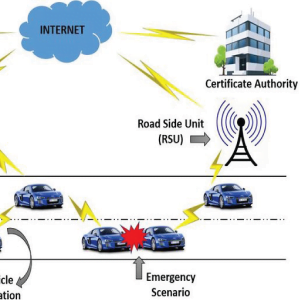

- Electrical vehicle (EV) applications

Customer Reviews

There are no reviews yet.